-

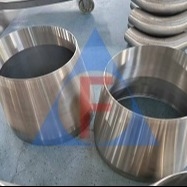

Phụ kiện ống titan

-

Ống hàn titan

-

Mặt bích ống titan

-

Ống Titanium liền mạch

-

Bộ trao đổi nhiệt Titanium

-

Ống cuộn titan

-

Tấm hợp kim titan

-

Chốt Titan

-

Dây hàn titan

-

Thanh tròn Titan

-

Titan rèn

-

Đồng mạ titan

-

Điện cực Titan

-

Mục tiêu phún xạ kim loại

-

Sản phẩm Zirconi

-

Bộ lọc xốp thiêu kết

-

Bộ nhớ hình dạng Dây Nitinol

-

Các sản phẩm Niobium

-

sản phẩm vonfram

-

Sản phẩm molypden

-

Sản phẩm Tantalum

-

Sản phẩm thiết bị

-

sản phẩm nhôm

-

Sản phẩm thép không gỉ

For Chemical, Marine, and Industrial Applications

Liên hệ với tôi để có mẫu và phiếu giảm giá miễn phí.

Whatsapp:0086 18588475571

wechat: 0086 18588475571

Ứng dụng trò chuyện: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp trợ giúp trực tuyến 24 giờ.

xProfessional Overview: Titanium Pipe Fittings for Critical Industrial Applications

As a supplier specialized in advanced metal components, I provide a comprehensive range of titanium pipe fittings designed to meet the rigorous demands of various high-performance industries. These fittings are extensively used in chemical processing, marine engineering, offshore structures, power generation (including nuclear and thermal), aerospace systems, and desalination plants, where material integrity, corrosion resistance, and mechanical reliability are essential.

Titanium, due to its outstanding strength-to-weight ratio, high resistance to corrosion, and excellent thermal stability, has become a material of choice for fluid handling systems in harsh environments. The pipe fittings I supply are manufactured in accordance with international standards such as ASTM B363, ASME B16.9, and MSS SP-43, ensuring dimensional accuracy and metallurgical consistency.

I offer fittings in a wide range of commercially pure and alloyed titanium grades to accommodate diverse operating conditions:

Grade 1 (GR1) and Grade 2 (GR2): Unalloyed titanium with excellent corrosion resistance, suitable for low-pressure applications and environments involving mildly reducing acids.

Grade 5 (Ti-6Al-4V, GR5): A titanium-aluminum-vanadium alloy widely used in aerospace and high-stress environments due to its high strength and fatigue resistance.

Grade 7 (GR7): Contains palladium for enhanced corrosion resistance in oxidizing media, making it ideal for chloride and acidic conditions.

Grade 12 (GR12): A titanium-molybdenum-nickel alloy offering superior strength, weldability, and resistance to crevice corrosion, often applied in heat exchangers and condenser systems.

Grade 16 (GR16): Similar to GR7, but with improved weldability and performance in chlorine-rich and oxidizing environments.

The product range includes but is not limited to elbows, tees, reducers, crosses, stub ends, and flanges, available in both seamless and welded forms. Each fitting undergoes strict quality control procedures, including chemical composition analysis, mechanical property testing, non-destructive examination (e.g., ultrasonic and dye penetrant testing), and pressure testing, to ensure compliance with project-specific requirements.

My objective is to deliver technically reliable, corrosion-resistant, and cost-effective titanium fitting solutions tailored to the specific operating conditions of each client’s application. Through a combination of material expertise, precision manufacturing, and responsive service, I support industries in enhancing operational efficiency and extending system life cycles.